semi-automatic valve applicator (JQ1)

Our semi-automatic valve applicator is the perfect solution for installing coffee one way degassing valve into your packaging,efficiency and stability, save energy and ensure reliable coffee packaging with our innovative solution.

Functions

1. The main material of the rack is the acrylic and aluminum materials.

2. Temperature control by temperature-controlled meter which is digital display, it is stable and reliable.

3. Time-controlled meter is adjustable, you can control the thermal bonding time, it suitable for a variety of packaging.

4. Equipped with a pedal switch, convenient hands operation.

5. The desktop design, it will move easily, and save more room, it is very beautiful and practical.

Advantages of semi-automatic valve applicator

![]() Energy saving: Low power consumption.

Energy saving: Low power consumption.

![]() Save cost: the price is cheaper.

Save cost: the price is cheaper.

![]() Durable: Made of high-quality materials to prevent machine oxidation and rust.

Durable: Made of high-quality materials to prevent machine oxidation and rust.

![]() Stability: Adopting a digital intelligent temperature controller, the time controller ensures the stability of the adhesive.

Stability: Adopting a digital intelligent temperature controller, the time controller ensures the stability of the adhesive.

![]() Safety: Manual or foot control, easy to operate.

Safety: Manual or foot control, easy to operate.

![]() Lightweight: Small in size, light in weight, and easy to move.

Lightweight: Small in size, light in weight, and easy to move.

![]() The HZJQ1 semiautomatic valve applicator is not only suitable for composite bags and multi-layer co-extrusion bags, but also suitable for the single-layer pure PE plastic bags, and to achieve stronger, faster, and more aesthetically pleasing welding.

The HZJQ1 semiautomatic valve applicator is not only suitable for composite bags and multi-layer co-extrusion bags, but also suitable for the single-layer pure PE plastic bags, and to achieve stronger, faster, and more aesthetically pleasing welding.

Remark :

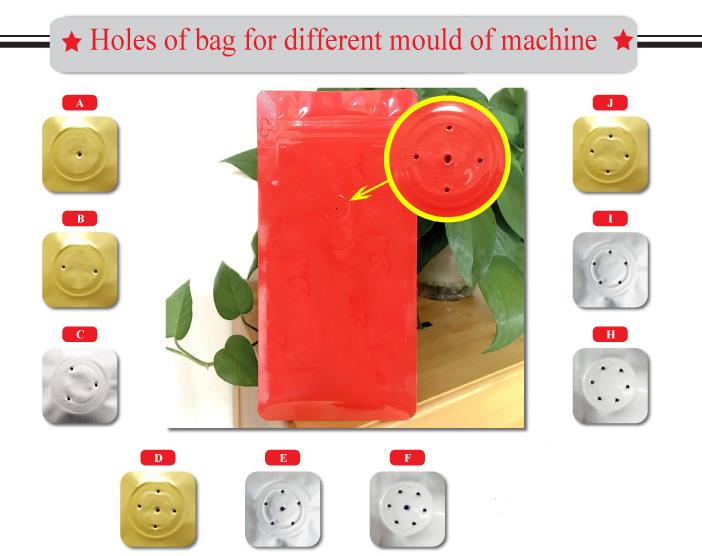

![]() Can customize different holes mould, it is very convenient and efficient.

Can customize different holes mould, it is very convenient and efficient.

![]() All our valve applicators need to use with the air compressor.

All our valve applicators need to use with the air compressor.

![]() The maximum distance of valve in coffee bag: about 15 cm from the pocket mouth to the middle of valve.

The maximum distance of valve in coffee bag: about 15 cm from the pocket mouth to the middle of valve.