automatic valve applicator (A6)

Automatic Valve Applicator – Hands-Free & High-Efficiency

Revolutionizing Packaging with Hands-Free Automatic Valve Output

The Automatic Valve Applicator is designed to enhance packaging efficiency by eliminating the need for manual valve placement. With its automatic valve output system, users no longer need to place degassing valves into the machine one by one by hand, ensuring a faster, more efficient, making it the perfect solution for businesses aiming for effortless degassing valve application.

Advantages of automatic valve applicator

1.Energy saving: Fast heating and power saving.

2.Exquisite process: Every part has been optimized and improved by engineers for many times to achieve the excellence of process production.

3.Save worry: Automatically deliver the one way degassing valve to the valve seat.

4.Safety: Touch the push plate with hand to press the valve, which is convenient for operation and high in efficiency.

5.Convenience: Integrated design, light and exquisite, convenient to move, small space occupation.

Remark

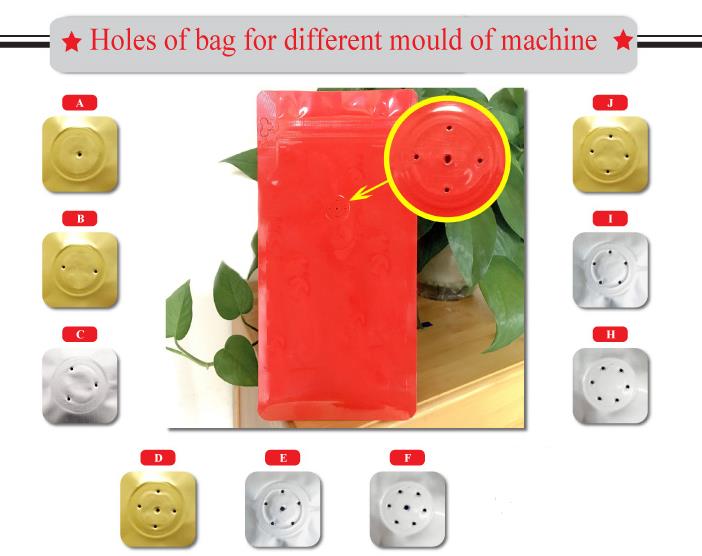

1. Can customize the pressure valve mold for different types of valves, it is very convenient and efficient.

2. Need to work with the air compressor.

3.The size of valve in coffee bag: about 15cm from the pocket mouth to the middle of valve.

Technical Specifications

Size: 32x51x44cm

Power Consumption: Low energy usage with fast heating

Speed: 1000-1300 per minute

Valve Compatibility: One way degassing valve

Operation: Fully automatic valve feeding and pressing

Material Compatibility: Foil bags, kraft paper bags, plastic pouches

Weight: Lightweight and portable